0

Sachets Per Day

0

Bottles Per Day

0

Metric Tonnes Annual Capacity

0

Capable and Skilled Workforce

0

Years of Trusted Partnership

The SDP Legacy

Building a Legacy of Trust and Excellence in Manufacturing

Southern Drugs & Pharmaceuticals (SDP) has been a trusted name in contract manufacturing, delivering world-class solutions to some of the most renowned global brands. Our journey began in 1991, when we partnered with GlaxoSmithKline (GSK)to manufacture ENO, a brand that millions trust every day. This enduring partnership is a testament to our uncompromising commitment to quality, precision, and operational excellence.

In 1999, we established our state-of-the-art manufacturing facility in Rajahmundry, Andhra Pradesh, scaling up our production capabilities to meet growing demand. Over the years, we have continued to invest in cutting-edge technology, automation, and sustainable practices, reinforcing our position as an industry leader in high-speed sachet and bottle production.

With an annual manufacturing capacity of 4,800 metric tonnes, producing 2.5 million sachets and 100,000 bottles per day, SDP has set benchmarks in efficiency, reliability, and global compliance standards. Our expertise extends beyond just production—we have pioneered cost-saving packaging innovations, implemented robotic automation for enhanced efficiency, and strengthened QMS with data integrity practices.

The SDP Legacy is built on a foundation of trust, excellence, and future-driven innovation. As we continue to evolve, our focus remains on empowering global brands, optimizing manufacturing processes, and setting new industry standards.

Southern Drugs & Pharmaceuticals – A Legacy of Manufacturing Excellence, Powering the Future.

Sahrud Bikkina

Executive Director

"We want to make the world a healthier place by supporting our business partners in manufacturing their impactful products. We strive for long-term value creation, leveraging our edge in manufacturing experience of over 30 years."

Capabilities

Our Strengths in Manufacturing

Manufacturing at Scale

SDP is built for high-volume, precision production, handling over 2.5 million sachets and 100,000 bottles per day with unparalleled efficiency.

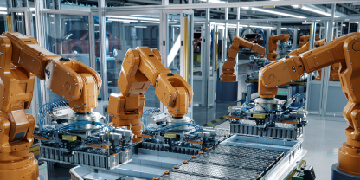

Advanced Automation

Our factory integrates cutting-edge robotics, to drive efficiency, minimise human error, and ensure seamless secondary packaging.

Regulatory & Compliance Excellence

We adhere to the highest quality standards, ensuring compliance global regulations.

Contract Manufacturing

Why Global Brands Choose SDP

Why Choose SDP for Contract Manufacturing ?

25+ years of experience with industry giants like GSK

Cost-efficient, scalable production

Cutting-edge automation for precision & consistency

Sustainability-driven innovations

The SDP Edge

What Sets Us Apart ?

Standards set for the facilities are not only maintained but efforts are being made and improve it further. Appreciate the team effort and the enthusiasm amongst all the team members.

World Class facility set up in a record time is Highly Appreciated. Each & every aspect was planned to the minute’s detail. Excellent efforts put in. Well done

It is indeed a pleasure and a great delight to visit a facility like this one. I appreciate the efforts made by the team and wish them all the best.

Having seen this facility from conception to completion ,i am delighted that the quality achieved has been world class. My Congratulations to all the team involved in this , and my best wishes for the future.

The facility is really world class. I will be the sales team to visit it & am sure it will inspire them to sell even must ENO & make India the biggest Eno market in the world.

Your adherence to quality ,environment ,health and safety reflects a high level of integrity and a commitment to supporting GSK on achieving its vision, as an equal partner.

Congratulations on all of your achievements especially in the area of environment ,health and safety.

Always a great pleasure to visit Southern drugs & Pharmaceuticals a well maintained with excellent standards site.

A Pleasure to return maintenance of operations is a credit to everyone at SDP. I wish you every Success in the future.

The skill is in maintaining the facility to the highest standard. You have excellent skills + very high standards. Good Luck for the future.

Congratulations to the whole team on the great Eno factory i have seen . I expect to double the business in the next 3 years and give you all a lead ache.

Great little factory where it has adopted GSK’s toolkit of best practices. Site also is very well maintains . I hope that increasing volumes and other business development opportunities will further forge our relationship.

A very nice facility that looks to run smoothly, good luck with growing volumes.

Impressed by the clean environment , efficient operations and quality of partnership between SDP and GSK.

A fabulous unit of a great facility .An incredibly knowledge workforce about both the product and the process. I learnt a tremendous amount about Eno today. Thank you.

The facility is maintained very well inside & out. The GMP’S are maintained for ayurvedic regs.Good diversity is maintained as the premises & certainly good place to visit & benchmark for ayurvedic.

Back again ! Amazing how the business looks so fresh. I left in 1999 with a challenge to management to maintain such a high standard .......and how they have !! Very best wishes for continued success.

A delightful facility and a real surprise for me to observe a high standard facility in this part of the world. Well done for maintaining high standards and best wishes for the future.

Very well maintained facility that has a high level of housekeeping. The infrastructure is very well kept and the work being done on gender diversity to increase female employment is commendable.

Very nice engineering applications in pouch filling and bottle capping. Well maintained operations. Congratulations on your 15 years of success & Wish you many more.

Great to see manufacturing operation of Eno. Impressed by continuous improvementatives by team for manufacturing operation , good 5 S and HK at site.

Site is very capable of Eno manufacturing .Lots of expertise and good to know the continuous improvement is going on. Looking forward for more strategic co-operation in other products as well.